The Strongest Splitters on the Market

With over 30 years of accumulative knowledge of design, manufacturing, mechanical and automotive experience, Flow Designs strives to bring fresh and innovative ideas to this industry, by exploring new manufacturing processes and recycled materials to become market leaders. Utilising these attributes, Flow Designs have innovated its current product range by manipulating recycled composite thermoplastics into a new revolution in aero styling. We are now widely known and distributed internationally, providing our customers with high-quality products.

Our Products

What is a Splitter Kit? A Splitter Kit is a custom-designed aerodynamic add-on that mounts to the underside of your vehicle’s front bumper, side skirts, and rear bumper. At Flow Designs Australia, our Splitter Kits are built for durability and style, enhancing your car’s appearance while providing protection against road debris. Perfect for daily drives or spirited runs, it’s a must-have for aesthetic upgrades and added protection.

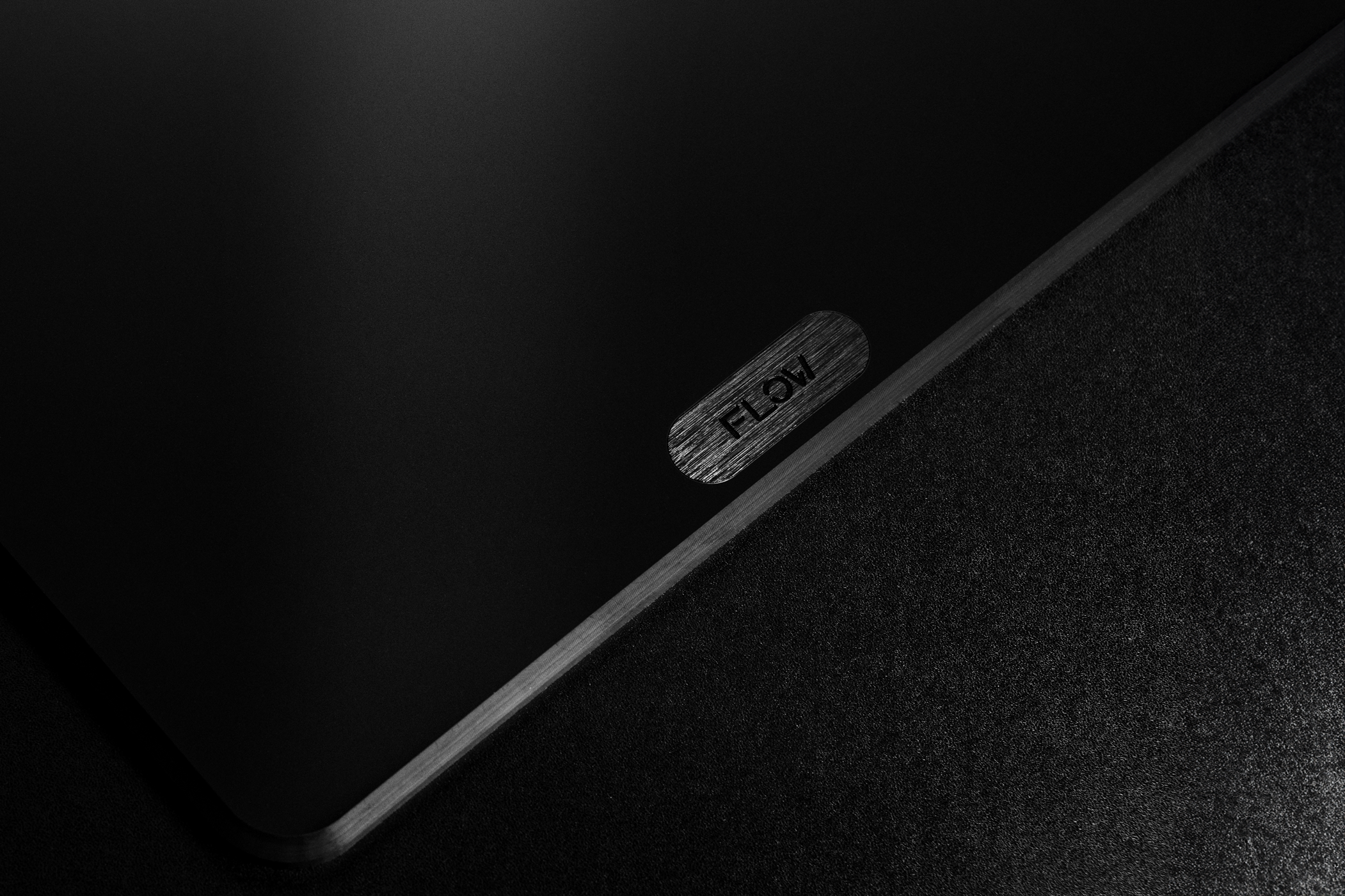

Two Unique Finishes

Our two unique finishes offer a consistent match to your vehicles OEM materials and finishes, leaving you with a seamless and pristine look. Our gloss finish offers a more premium appeal with a high reflective finish, compared to our Textured finish that is scratch resistant and durable for easier maintenance.

Premium Reflective

Gloss Finish

Scratch Resistant

Texture Finish

Latest Release

Our All new i30N Sedan Facelift Splitter Kit

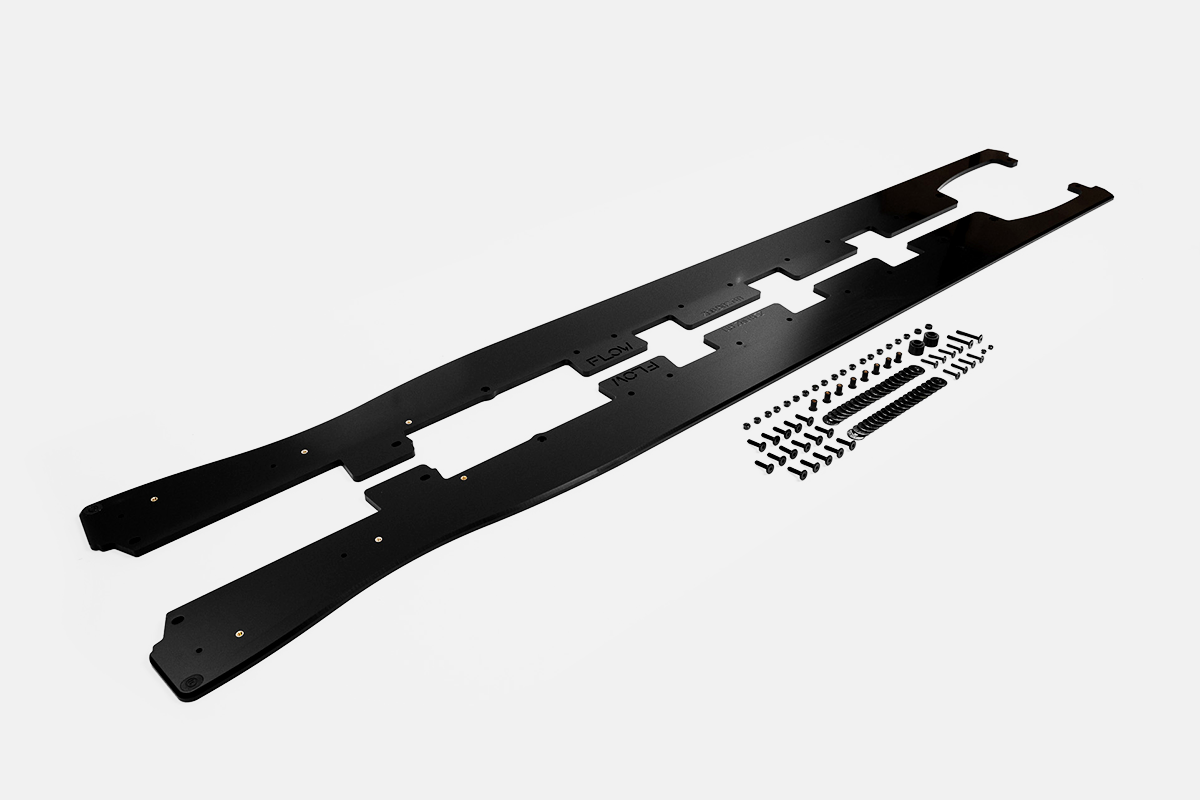

CN7 V2 i30N Sedan FL 2024 Full Lip Splitter Set

CN7 V2 i30N Sedan FL 2024 Rear Spats (Pair)

How are our products made?

Step One

Examine the Car

The production process begins with a thorough walkaround inspection of the vehicle to assess its overall shape, underbody layout, and any unique characteristics that may impact the design and installation of the splitter kit. During this stage, our team identifies potential challenges, irregularities, and variations that may affect fitment. This detailed evaluation helps determine the specific requirements for the kit—such as whether custom chassis mounts, specialized brackets, or unique hardware will be necessary. Every aspect is carefully considered to ensure the final product offers a precise fit, uncompromised functionality, and seamless integration with the vehicle's factory lines.

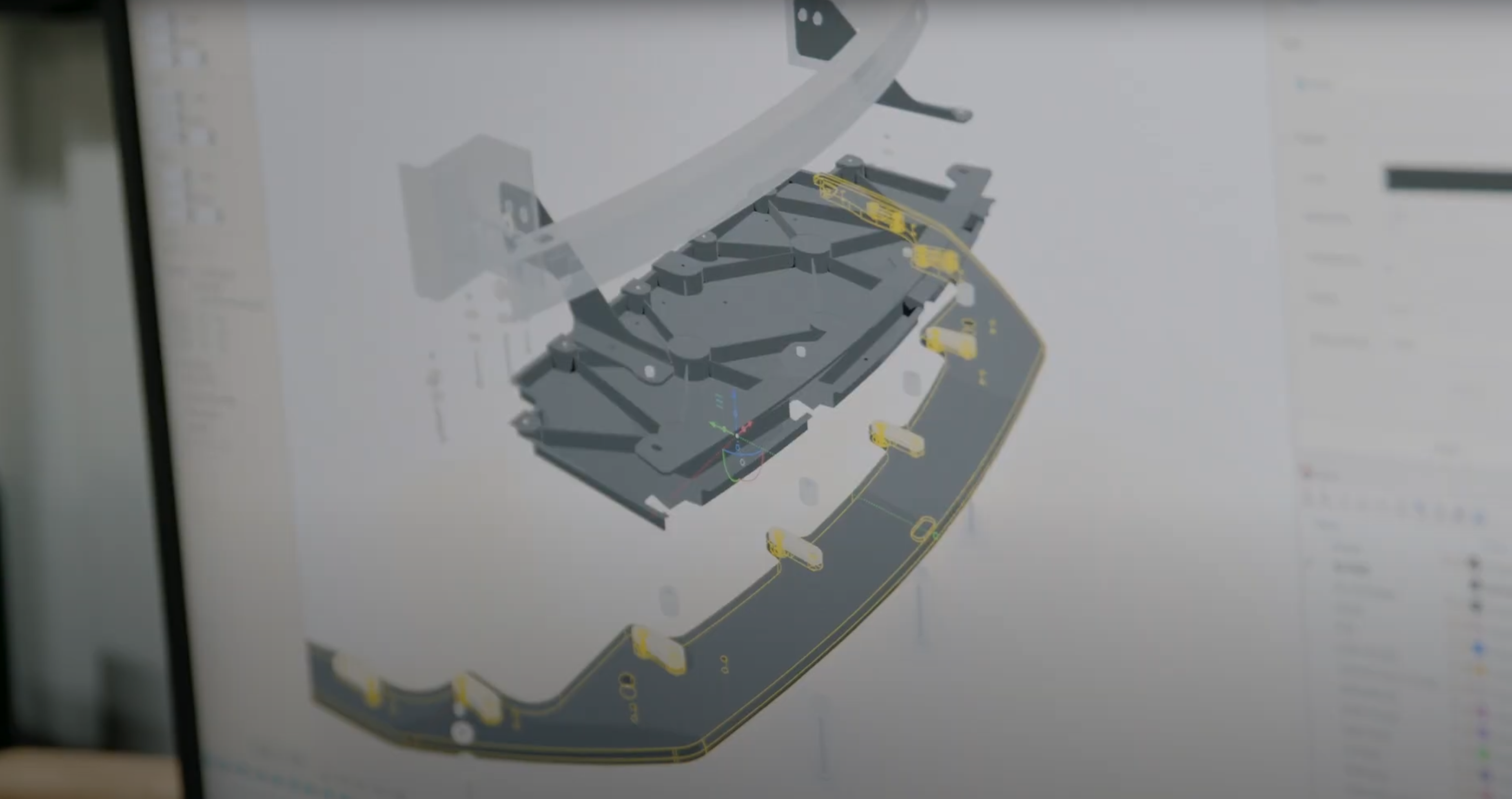

Step Two

Project Preparation

The next phase is the design and development of the splitter components. Using insights gathered during the initial inspection, the designer begins conceptualizing a splitter that complements the car’s aesthetic while meeting functional and structural requirements. This includes carefully considering the shape, size, and contours to ensure optimal fitment and visual integration with the vehicle's existing lines. A rough prototype is then created using a specialized development material, allowing the team to conduct a physical test fit directly on the car. This hands-on step is crucial for evaluating proportions, clearance, and potential mounting points, and it serves as the foundation for further refinement before final production begins.

Step Three

Creating Product Forms

With the design finalized, the process moves from concept to physical realization. Using the approved design data, our team begins creating precise product forms—three-dimensional representations of each individual component in the splitter kit. These forms are carefully developed to capture every curve, angle, and detail of the original design, ensuring that each piece is both visually accurate and functionally sound. This step is critical in translating the digital model into a tangible format that can be used for further prototyping, testing, and eventual production, maintaining the integrity and quality Flow Designs is known for.

Step Four

Product Testing

Once the prototype components have been formed, the process moves into the product testing phase. Each part is rigorously assessed for fitment, strength, and overall functionality on the vehicle. The splitters are mounted and evaluated under real-world conditions to identify any issues with alignment, clearance, or structural integrity. This stage also involves testing the hardware and mounting systems to ensure secure installation and long-term durability. If necessary, refinements are made to the design or mounting points to guarantee a perfect balance of aesthetics, performance, and safety. Product testing is a crucial step in upholding the high standards of quality and precision that Flow Designs is known for.

Step Five

Final Evaluation

The final evaluation marks the last step before a splitter kit is approved for production. The complete prototype is reinstalled on the vehicle and thoroughly checked for fitment, design accuracy, and overall finish. The team ensures all components align correctly, are securely mounted, and integrate seamlessly with the vehicle. Once the product meets Flow Designs’ standards for quality and performance, it’s approved for full-scale manufacturing.

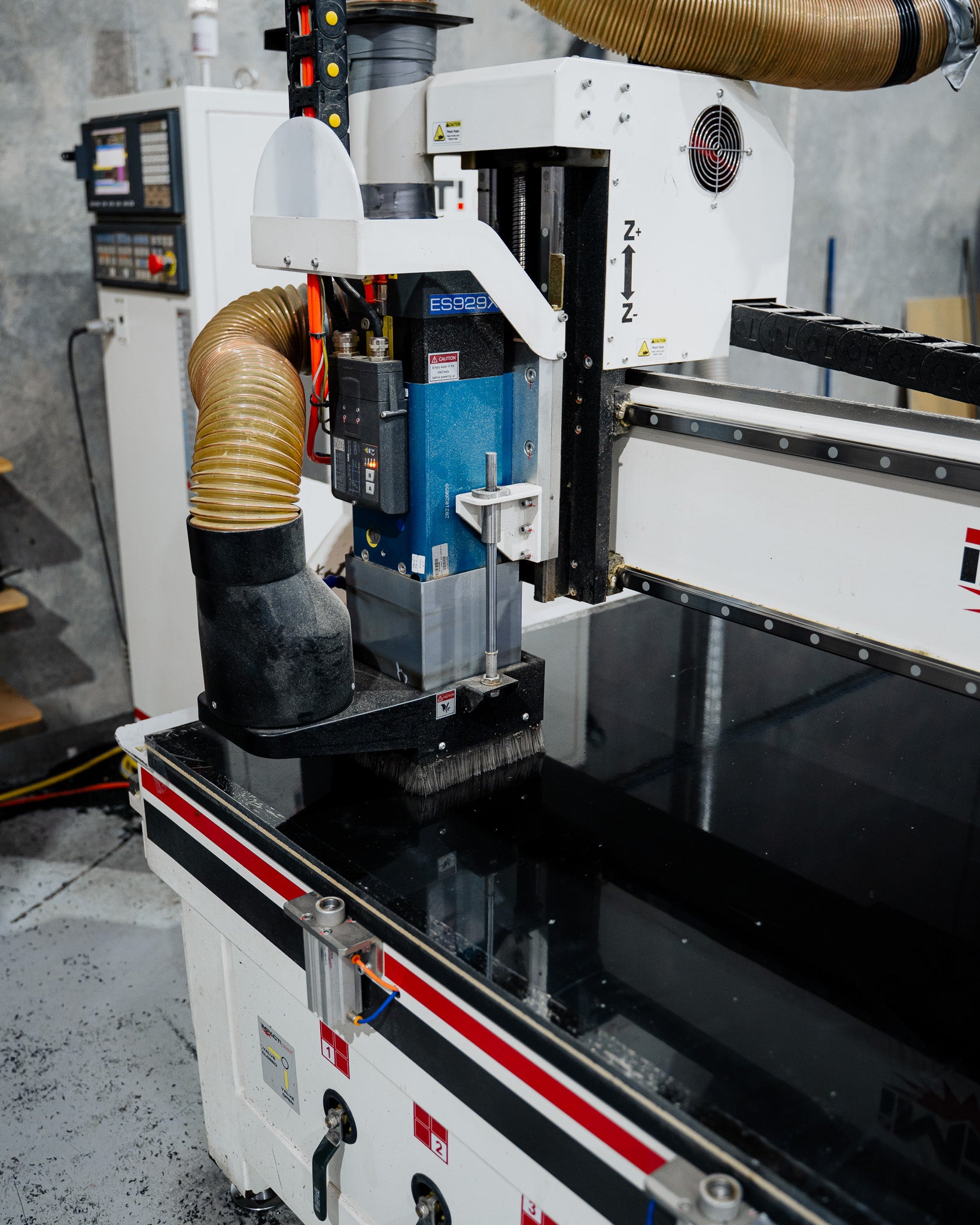

Step Six

CNC Processing

With the design finalized, the process moves to CNC testing, where an initial cut is performed using our in-house CNC machinery. This test ensures that the toolpaths are optimized for precision, material integrity, and cutting efficiency. During this stage, we evaluate the accuracy of the cut, adjust speeds and tooling if necessary, and make refinements to streamline the process for large-scale production. Any changes are implemented to improve consistency, reduce waste, and increase overall manufacturing efficiency—ensuring each part is produced to Flow Designs’ high standards with maximum productivity.

Step Seven

Securing and Packaging

Once all components have passed final checks, they move into the securing and packaging stage. Each splitter piece is carefully cleaned, inspected one last time, and protected with durable packaging materials to prevent damage during transit. Hardware and fitting instructions are included, and all items are securely packed into custom-sized boxes to ensure safe and efficient delivery. This attention to detail ensures that customers receive their Flow Designs kit in perfect condition, ready for installation straight out of the box.

Step Eight

Creative Campaign and Launch

With production complete, the focus shifts to the creative campaign and product launch. Our media team captures high-quality photography and videography to showcase the splitter kit's design, fitment, and unique features across a variety of platforms. Carefully curated content is then used to build anticipation and drive engagement through social media, email marketing, and our official website. Launch assets are strategically timed to align with market demand and audience interest, ensuring the product reaches the right customers at the right time. This final step not only highlights the craftsmanship behind each kit but reinforces the Flow Designs brand as an industry leader in automotive styling solutions.

Detailed Installation Guides

All of our splitter kits come with an easy mounting solution to make installation effortless, allowing you to drive around in your new kit in no time. With our helpful instructional videos we break down the process making it even easier to assemble yourself.

Hidden Features

Our Flow Designs Splitter Kits aren't just any ordinary Kit, we custom make everything down to the bone, front custom sainless steel hardware, to custom chassis mounts for unbeatable strength, all to back out 10 Year Warranty.

Unbreakable Finishes

We offer two premium finishes to suit different styles and uses:

- Gloss Black - High-shine, premium look ideal for modern and Euro vehicles

- Textured Black - Scratch-resistant and durable, great for track use and easy maintenance

- Both are designed to match OEM materials for a clean, seamless fit

Our two unique finishes offer a consistent match to your vehicles OEM materials and finishes, leaving you with a seamless and pristine look.

Our gloss finish offers a more premium appeal for those with European and modern day vehicles with a high reflective finish, compared to our

Textured finish that is scratch resistant and durable for those wishing to track use their car and have easier maintenance.

Stainless Steel Hardware

We use premium stainless steel hardware built for long-term durability:

- Rust and corrosion-resistant for all-weather reliability

- Custom-engineered brackets designed for strength and stability

- Built to last over 10 years, even with heavy use

- High-quality materials ensure performance without compromise

We use only custom made, premium-grade stainless steel for all our hardware, ensuring exceptional durability and resistance to rust and corrosion.

Each component, from the smallest screw to the mounting brackets, is meticulously designed and manufactured to withstand the test of time.

Our custom-engineered brackets and mounting hardware are specifically crafted to provide maximum stability and strength, guaranteeing that your parts hold up over a full 10 years or more in any conditions.

By focusing on quality materials and thoughtful design, we deliver parts that not only look great but also stand up to heavy use without compromising performance.

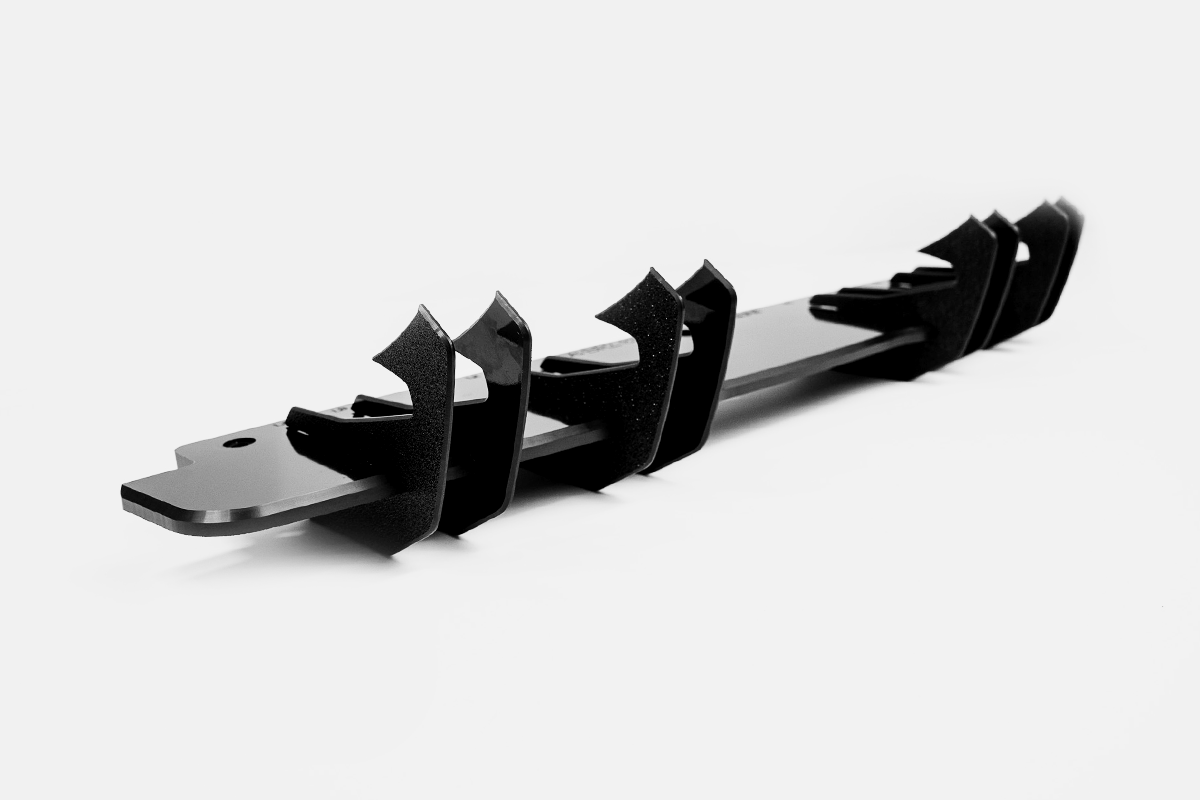

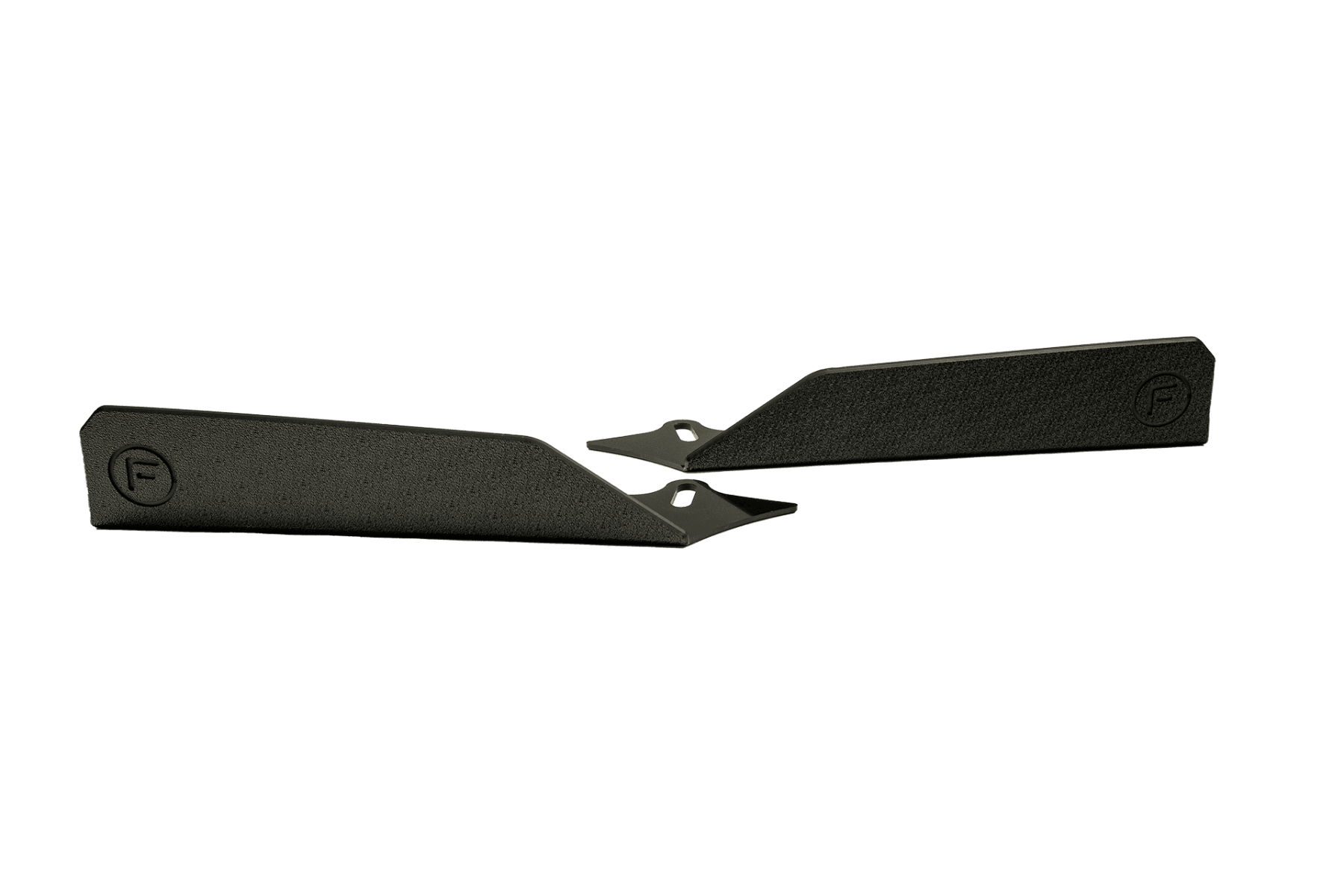

Flow-Lock Technology

Diffuser Fins without fasteners.

Our Flow-Lock mounting system keeps diffuser fins secure without the need for fasteners or messy brackets:

- Snap-lock system for quick, tool-free installation

- Clean and seamless finish with no exposed hardware

- Durable design that won’t break or shift over time

- Eliminates the need for brackets or visible fasteners

Our Flow-Lock mounting system snaps securely into place, delivering a clean, seamless finish—no messy brackets, no visible fasteners, and no risk of failure.

Would you like a shorter version for social media or product listings?

Chassis Mounting

Chassis-Mounted Brackets – Built for Strength & Stability

- Custom-designed metal brackets mount directly to the vehicle’s chassis.

- Engineered through extensive testing to maximise structural support.

- Designed to distribute load to the strongest points of the vehicle.

- Reduced flexing, sagging, or detachment over time.

- Keeps the splitter performing and looking as intended, long-term.

Some of our front splitters feature custom-designed metal brackets that mount directly to the chassis. These brackets aren’t just an afterthought — they’re the result of extensive testing and design refinement. By distributing load across stronger structural points of the vehicle, they significantly improve the strength and stability of the splitter, especially at high speeds or under stress. This ensures your splitter stays firmly in place, maintains its shape, and performs exactly as intended.

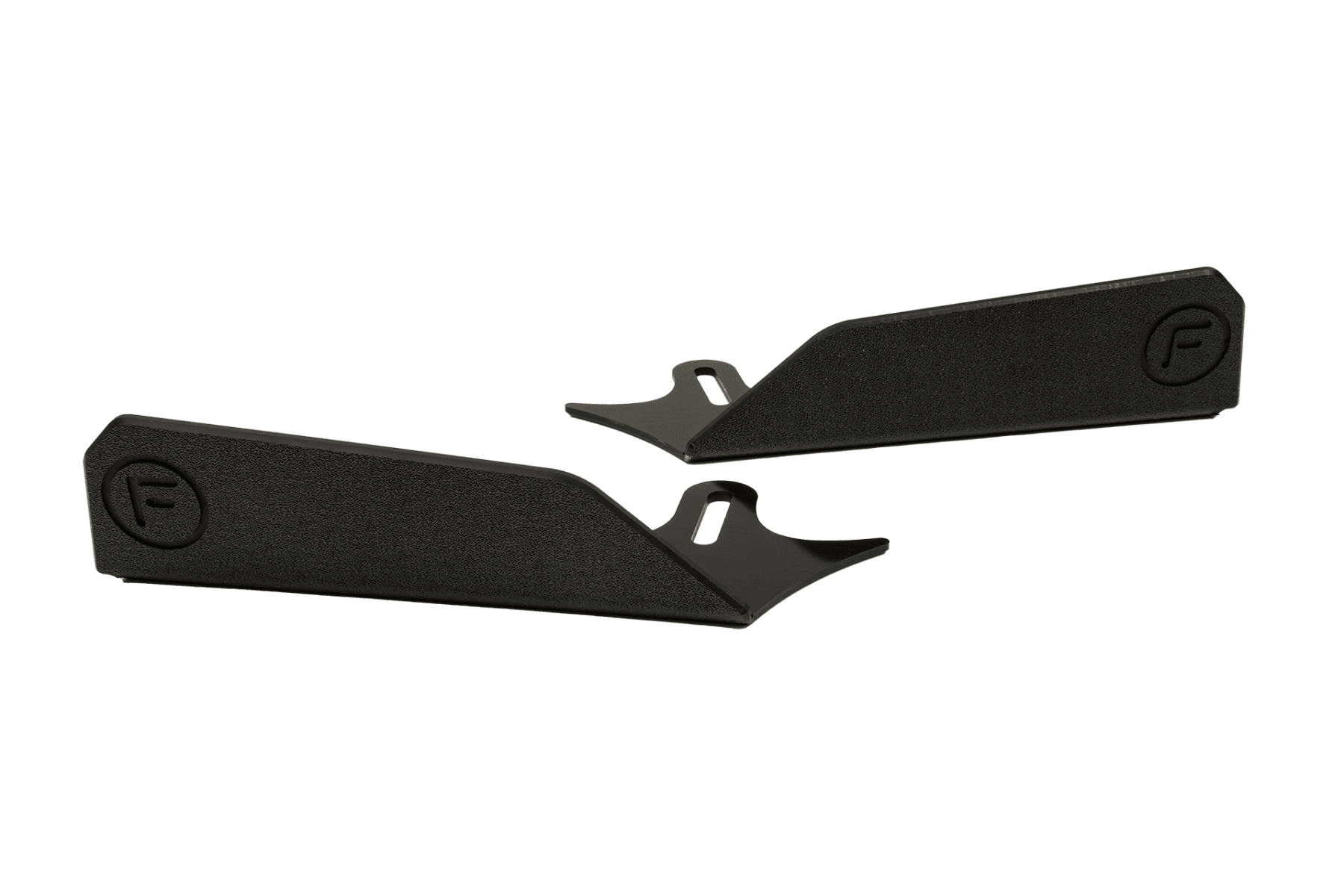

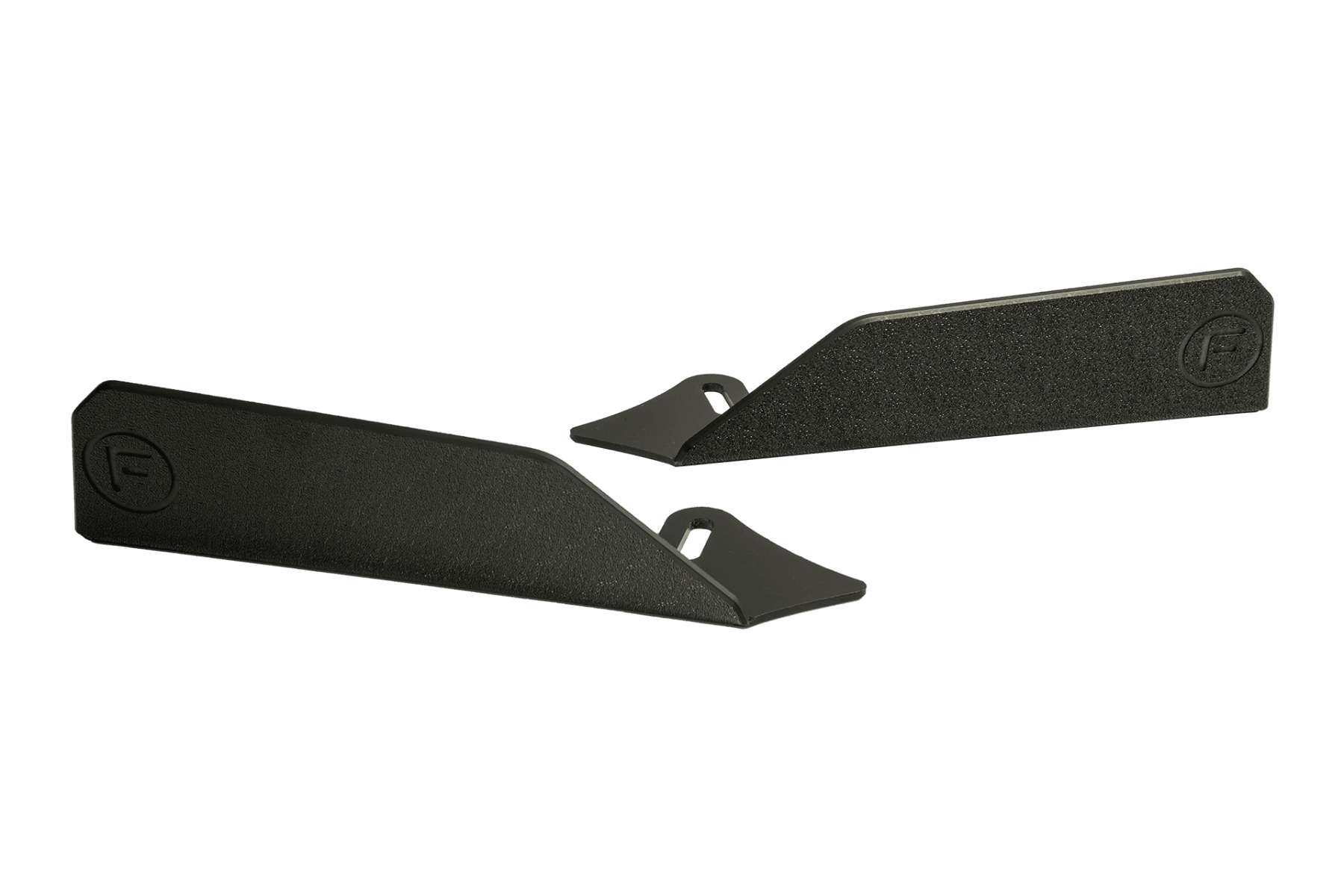

Fully Customizable

Customisable Styling with Winglets & Extensions

Flow Designs splitters already enhance vehicle individuality — but we take it further.

- Add Adjustable Winglets or Front Extensions to personalise your setup to your exact taste.

- Perfect for creating a wider, more aggressive stance to match your build.

- Fully modular design lets you choose how subtle or bold you want to go.

- We engineered the first bolt-on system that integrates directly with our splitters.

- No messy L-brackets — just a seamless, purpose-built solution.

- Pre-installed brass threads allow for easy adjustments using only an allen key.

Having a Flow Designs splitter on your car automatically adds to its uniqueness - but we wanted to push it one step further because we know our customer base is about automotive customisation and styling.By offering Winglet and Front Extensions to our various splitter sets and designs, we allow you to push the boundaries of custom auto styling to whatever suits your taste.

Need a more aggressive splitter to match the the wide stance of your ride? No problem, add a Winglet Extension and you can choose exactly how wide you want to take it.

Again with simplicity and the customer in mind, we are the first to create an integrated bolt-on system that specifically pairs with our splitters - we don't just throw on a winglet or hold it up with an L-bracket. Our pre-installed brass thread gives you the flexibility to easily bolt-on and adjust the extensions and winglets with just an allen key.

The First Unbreakable Splitter

We're known worldwide as the manufacturer of splitters that don't crack, and we are so sure of this so we back all of our Splitters with a 10 YEAR Warranty, which we are sure you will never use.

MK7 Golf R (EU/AU) Full Lip Splitter Set

Shop the Feed

Best Sellers

CN7 V2 i30N Sedan FL 2024 Full Lip Splitter Set